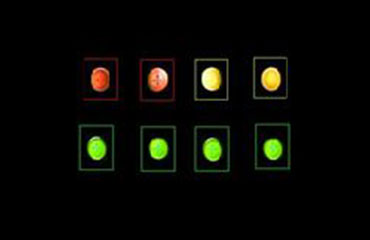

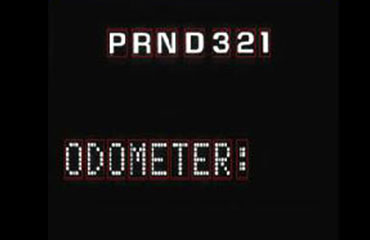

We have experience in different applications that involved Machine Vision Systems and functional Test & Measurement Systems.

The following are some examples of Machine Vision applications applied on the Automotive and Manufacturing Industry:

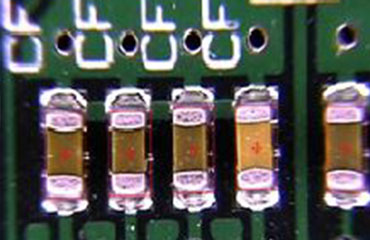

Solder Inspection

This system verifies the quality and solder insufficiency on the pads, the system also uses motion control to move the main fixture with the Unit Under Test to different test positions.